- Joined

- Dec 23, 2009

- Messages

- 1,165

- Reaction score

- 25

- Moderator

- #1

Recently ran into a slight problem while setting up my Thumb BO5. After adjusting the bridge height I discovered the threads in the base plate for the locking screw of the 3D bridge were stripped. While it isn't super critical that this be tight since string pressure will keep it held down, I didn't want it loose either. I decided to fix it myself and documented the process.

WARNING: PROCEED AT YOUR OWN RISK. Neither Warwick or myself are responsible for any damage you cause during this process.

A side note: I went about this method because I couldn't find any thread repair inserts small enough (if they even go this small) in my area so this was the next best option.

First off here are some materials and tools you'll need.

Directions:

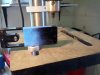

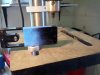

The first thing you'll need to do is obviously remove the bridge and then the base plate from the guitar. Once it's removed take your drill and a drill bit larger than the existing hole and drill out the bad threads as show below. Try to do this on a level surface and drill as straight as possible. At this point it's not super critical since we're just making a bigger hole and the bit will "chase" the existing hole. If you have access to one, use a drill press as shown in the pic. Remember to drill slowly and wear eye protection.

After drilling you should have a nice clean hole and all the old threads should be removed. At this point I like to take a metal file and knock down any burrs that are left over. This will help in the next few steps when applying the repair epoxy.

At this point we're ready to apply the repair epoxy. In this situation we're going to use a product called JB Weld. If this isn't available in your country try and find a suitable metal repair epoxy.

Lay down some paper or other material to protect the surface you're working on. Now follow the instructions for using your chosen repair epoxy. With JB Weld you mix the epoxy and hardener 1:1 or equal parts of each. Mix until you get a uniform consistency. It's a good idea to put something under the hole such as masking tape to keep the epoxy from escaping out from the bottom. You can also notice the size difference of the original hole and the newly drilled out hole.

After mixing the epoxy it's time to apply it. Scoop a little bit up with the corner of an old credit or debit card or other suitable applicator. Let the epoxy drip into the hole so that it fills up evenly. I like to press the epoxy down into the hold a bit with the card and then drop a small amount of epoxy on top to create a bead. It's easier to remove a little excess epoxy than it is to re-apply after the fact. This is also the reason why we de-burr the hole so that it makes it easier to apply the epoxy. At this point we wait for the epoxy to cure.

Once the epoxy is cured (I let it sit for 24hrs before handling) it's time to sand off the excess epoxy and remove the tape from the back of the bridge plate. At this point I wrapped the area of the plate I wanted to protect with some masking tape.

Here's the top of the bridge plate.

Now here's the bottom with the tape removed.

Once you've removed all the excess epoxy it's now time to mark the center of the hole so that you can drill your pilot hole for thread tapping. It's very important that you get this as close as possible. There is a little give in the bridge if you're off a bit but not much. Take your time getting this part right. Since I drilled the first hole using a 5mm bit, I measured from the edges of the hole to the center which is of course 2.5mm. Do this in both directions to find center. Make your marks and then place the bridge onto the plate to be absolutely sure your holes will line up.

Once you've marked your hole it's time to drill your pilot hole. Again, take your time as this step is very important. You need to drill this hole as perpendicular to the base plate as you possibly can. If you have access to a drill press, this is the time to use it!

Now we need to add some threads to our pilot hole. Take the appropriate sized hole tap and insert it into the pilot hole. Add some downward pressure as you twist the tap to help the tap get a bite onto the hole and start cutting threads. Do this until the tip of the tap exits the bottom of the hole. From there you can turn the tap normally to finish cutting the threads.

After you've cut the new threads it's time to test the screw in the hole. It's also a good idea to place the bridge onto the plate and try it again to make sure everything lines up properly.

If everything lines up you're all set! Now all that's left is to paint the sanded area.

After the paint has dried, install the plate and bridge and restring your bass and check the set up. You should now be able to tighten the locking screw again. Hopefully this how to will be of some help and save you a few dollars if you run into a similar issue.

WARNING: PROCEED AT YOUR OWN RISK. Neither Warwick or myself are responsible for any damage you cause during this process.

A side note: I went about this method because I couldn't find any thread repair inserts small enough (if they even go this small) in my area so this was the next best option.

First off here are some materials and tools you'll need.

- Proper tools to remove bridge and base from the guitar

- Electric drill and drill bits for metal

- Metal file

- JB Weld or other metal repair type of epoxy

- Something flat and smooth such as a credit/debit card to smooth the epoxy

- Metric tap and die set

Directions:

The first thing you'll need to do is obviously remove the bridge and then the base plate from the guitar. Once it's removed take your drill and a drill bit larger than the existing hole and drill out the bad threads as show below. Try to do this on a level surface and drill as straight as possible. At this point it's not super critical since we're just making a bigger hole and the bit will "chase" the existing hole. If you have access to one, use a drill press as shown in the pic. Remember to drill slowly and wear eye protection.

After drilling you should have a nice clean hole and all the old threads should be removed. At this point I like to take a metal file and knock down any burrs that are left over. This will help in the next few steps when applying the repair epoxy.

At this point we're ready to apply the repair epoxy. In this situation we're going to use a product called JB Weld. If this isn't available in your country try and find a suitable metal repair epoxy.

Lay down some paper or other material to protect the surface you're working on. Now follow the instructions for using your chosen repair epoxy. With JB Weld you mix the epoxy and hardener 1:1 or equal parts of each. Mix until you get a uniform consistency. It's a good idea to put something under the hole such as masking tape to keep the epoxy from escaping out from the bottom. You can also notice the size difference of the original hole and the newly drilled out hole.

After mixing the epoxy it's time to apply it. Scoop a little bit up with the corner of an old credit or debit card or other suitable applicator. Let the epoxy drip into the hole so that it fills up evenly. I like to press the epoxy down into the hold a bit with the card and then drop a small amount of epoxy on top to create a bead. It's easier to remove a little excess epoxy than it is to re-apply after the fact. This is also the reason why we de-burr the hole so that it makes it easier to apply the epoxy. At this point we wait for the epoxy to cure.

Once the epoxy is cured (I let it sit for 24hrs before handling) it's time to sand off the excess epoxy and remove the tape from the back of the bridge plate. At this point I wrapped the area of the plate I wanted to protect with some masking tape.

Here's the top of the bridge plate.

Now here's the bottom with the tape removed.

Once you've removed all the excess epoxy it's now time to mark the center of the hole so that you can drill your pilot hole for thread tapping. It's very important that you get this as close as possible. There is a little give in the bridge if you're off a bit but not much. Take your time getting this part right. Since I drilled the first hole using a 5mm bit, I measured from the edges of the hole to the center which is of course 2.5mm. Do this in both directions to find center. Make your marks and then place the bridge onto the plate to be absolutely sure your holes will line up.

Once you've marked your hole it's time to drill your pilot hole. Again, take your time as this step is very important. You need to drill this hole as perpendicular to the base plate as you possibly can. If you have access to a drill press, this is the time to use it!

Now we need to add some threads to our pilot hole. Take the appropriate sized hole tap and insert it into the pilot hole. Add some downward pressure as you twist the tap to help the tap get a bite onto the hole and start cutting threads. Do this until the tip of the tap exits the bottom of the hole. From there you can turn the tap normally to finish cutting the threads.

After you've cut the new threads it's time to test the screw in the hole. It's also a good idea to place the bridge onto the plate and try it again to make sure everything lines up properly.

If everything lines up you're all set! Now all that's left is to paint the sanded area.

After the paint has dried, install the plate and bridge and restring your bass and check the set up. You should now be able to tighten the locking screw again. Hopefully this how to will be of some help and save you a few dollars if you run into a similar issue.